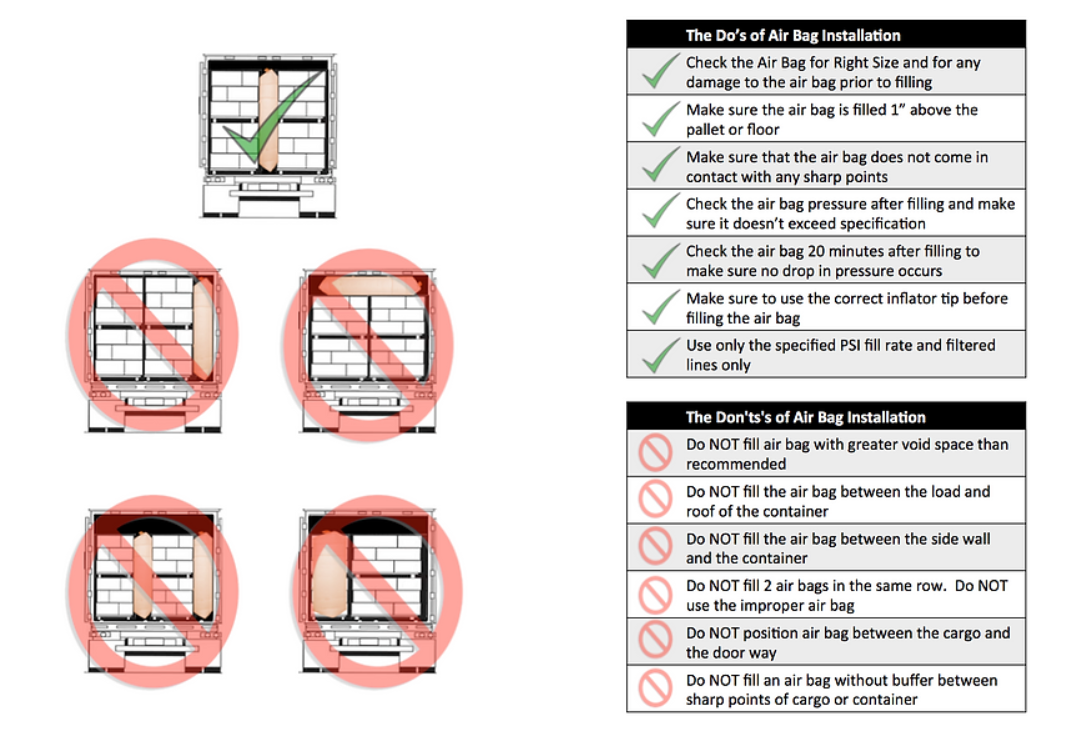

As in anything, if dunnage air bags are not properly filled or handled, it is doomed to fail. we are happy to teach you how to properly store, handle, install, check and deflate air bags. Below are the

basics of handling dunnage air bags. To ensure that you have proper securement, follow these basic steps.

Quality Focus

We puts a high focus on inspection and testing of our inflatable dunnage air bags. A single knick, pin hole, or faulty valve is unacceptable thus we put forth a strong quality program to make sure that the product meets and exceeds industry standards. We test a minimum of 16% of all air bags made, check pressure after 2 minutes, then again after 20 minutes to make sure it passes the standard we use.

If any failures are found, we double the amount of bags checked. If any more are found out of that order, we check 100% for that day's production.

We also check all inbound materials for burst test requirements to make sure all products meet and exceed the product's requirement.

Our Product Range

we have the ability to manufacture the Polywoven Dunnage Air Bags. In case of paper dunnage air bags, we will be glad to offer your Paper Dunnage Air Bags in stead.